| |

|

|

|

ELRO® Peristaltic Pumps, Accessories/Automation

ELRO® Peristaltic Pumps can be fitted with a variety of accessories, even in the field of automation. ELRO® Peristaltic Pumps can be fitted with a variety of accessories, even in the field of automation.

The range of accessories comprises coupling systems, suction and discharge hoses, various suction strainers, disc strainers, vacuum strainers and suction pipes. Active and passive pulsation dampeners are also available for the peristaltic pumps in a variety of material combinations.

be equipped with mechanical and electronic switching equipment, sensors, early warning systems, heating, dosing and filter press controls for monitoring purposes, open loop and closed loop control. |

ELRO® Peristaltic Pumps, Series GP20/10 EX and GUP3-1,5

Pumps for Hazardous Materials and Disposal Systems Pumps for Hazardous Materials and Disposal Systems

Disposal Professionals rely on ELRO® Pumps for Hazardous Material and disposal systems GP 20/10 Ex and GUP 3-1,5.

The number of applications in fighting accidents involving hazardous materials (chemicals, mineral oil products, pesticides and many others) is increasing alarmingly. Therefore fire departments, technical support, works safety and protection service or the armed forces are increasingly faced with new problems and higher demands placed on personnel and devices.

Fluids that have escaped in an accident endanger human life, animals and the environment. These hazardous materials have to be absorbed fast and completely in safe receptacles. By doing so even the mixing with dirt, grit or foliage not impede the suction or pumping.

Important: Ready for Instant Use!

The hazardous material pumps GP 20/10 Ex and GUP 3-1,5 are explosion-proof and can be used immediately . They are fast, dry and able to easily transfer solid-containing, viscous or pulpy media. When using the drum disposal self-priming system (accessories), the hazardous material does not come into contact with the actual pump.

Due to the particularly high suction power (by using the special accessories) even residues and thin liquid films are absorbed. The pump’s function is not impaired by possible intake of air. |

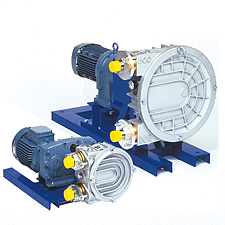

ELRO® Peristaltic Pumps, Series XP

ELRO® peristaltic pumps series IP are designed for the reliable, stationary application in the industrial field. They feature neither valves nor product wetted shaft seals. ELRO® peristaltic pumps series IP are designed for the reliable, stationary application in the industrial field. They feature neither valves nor product wetted shaft seals.

The newly developed ELRO® peristaltic pumps of the XP series provide a high flow rate at low speeds. The large peristaltic hose cross section enables the delivery of media with very high solids content.

The XP series is equipped as standard with the newly developed vacuum system integrated directly into the pump housing. The highly engineered peristaltic pump hoses provide outstanding suction qualities and also provide very long hose service life.

Main areas of application:

- Wastewater Industry

- Chemical Industry

- Environmental Industry

- Construction Industry

Numerous economic and technical advantages result from the new design, such as:

- Extremely high flow rate up to 46m3/hr at constant speed

- Proven compact design

- Safe to run dry

- Integrated vacuum system

- Dry suction lift to 9.5 m

- Delivery of high-viscosity products with vacuum support

- Maximum delivery pressure of 13 bar

- Ideal for fibrous materials and solids up to 60 mm due to large hose diameter

- Standard suction and delivery lines available

- Constant flow rate over the entire service life through vacuum support

- A variety of hose and fluid connection materials are available

|

ELRO® Peristaltic Pumps, Series M 300

The mobile All-Purpose Pumps with high Suction Capacity The mobile All-Purpose Pumps with high Suction Capacity

The mobile all-purpose pumps with high suction capacity.

- Compact, easy to handle, lightweight

- Transferred medium does not come into contact with the internal pump parts

- Various hose and connection materials available

- Dry self-priming up to 9.5 mWS (374” WC)

- Flow rate 15m3 (3953) or 20 m3(5284)/h (US gal)

- Flexibly applicable due to versatile accessories

Various designs ensure individual, efficient discharge, e.g. slurries, contaminated and viscous fluids with any solids, fibers, abrasive media etc.

All designs are compact, lightweight and mounted in a carrier frame as standard.

The pumps are optionally available with electric (also EX), gasoline, diesel or hydraulic drive.

Main fields of Application:

- cleaning of tanks and containers

- draining of tank routes and shafts

- disposal of waste oils

- faeces and paint slurries

- dewatering with excavations

- on-board pump on tank trucks

- emergency pump at leakages etc.

|

ELRO® Peristaltic Pumps, Series IP

Power package for the economic range

ELRO® peristaltic pumps series IP are designed for the reliable, stationary application in the industrial field. They feature neither valves nor product wetted shaft seals.

The medium to be transferred comes in contact only with the hoses inside. These pumps are especially suitable for the discharge of abrasive, long-fiber or aggressive media as well as fluids of high viscosity or shearing sensitivity. The patented “hose in hose vacuum system” yields numerous technical and economic advantages. The pumps are dry self-priming up to a suction head of 9.5 m (374”). Owing to the integrated vacuum system they feature a constant flow rate.

The early warning system warns of a hose defect possibly arising from normal wear. The pump bodies are filled with special glycerine or silicone for heat dissipation. An infinitely variable control of the flow rate is made possible by implementing frequency-converter controlled motors or mechanical control gear motors.

Suitable for difficult media, e.g. viscous slurries, abrasive materials, fibers and other solids as well as liquid and gas mixtures.

-

Without any valves and product wetted shaft seals.

-

Dry self-priming up to a suction head of 9.5 m (374”).

-

Suitable for shear-sensitive media.

-

Flow rates of up to 28m3/h (7398 US gal/h).

-

Good dosing performance, easy in-line cleaning.

-

Dry-running resistant over short periods of time.

-

Warning of hose defects by the integrated early warning system.

|

|

|

|

|

|

|

|

|

Contact for |

| Address : |

|

|

FF-18, Sardar Complex, Opp. Bhagvan Nagar,

Nr. Govind vadi, Isanpur, Ahmedabad - 382443. Gujarat, India.

|

|

|

|

E-Mail :

Phone :

Fax :

|

|

|

info@hinuc.net

sales@hinuc.net

+91 - 79 2538 2108

+ 91 - 79 - 25395415 |

|

| Website : |

|

|

www.hinuc.net

|

|

|

|

|

|

|